Precision sample delivery is critical for high quality SPR data. A poorly delivered sample makes SPR analysis challenging and error prone in that it is difficult to discriminate the difference between true binding behavior and spurious secondary effects. This is typically manifested as data with non-ideal binding profiles and high irreproducibility. The main underlying factor contributing to poor sample delivery is often dispersion.

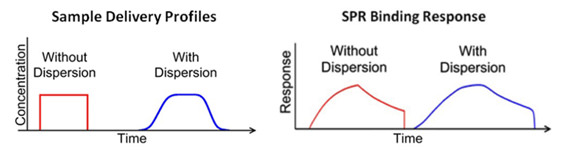

BI-DirectFlow™ technology delivers sample to the sensor surface with near-zero dispersion to generate high quality data that more clearly distinguishes true binding events from the secondary effects. Dispersion results from the inter-mixing of sample and buffer solutions during sample delivery, and occurs at both the front and back ends of the sample plug. These inter-mixed regions form distorted concentration profiles so that the sample introduction and removal at the sensor surface is not sharp, but rather is gradual over time. Figure 1 illustrates the difference in how the concentration profiles for a sample delivered with and without dispersion may appear. Notice how the concentration profile of the dispersed sample (right) has a rounded shape. This generates a deformed SPR response with poorly defined binding analysis regions, such as the curve shown on the right in Figure 1. Note how the binding response on the left (without dispersion) has very sharp, well-defined binding analysis regions. Conversely, the binding response on the right (with dispersion) has blurred, poorly defined binding analysis regions. Although the binding data on the right may be sufficient for many affinity and some kinetic binding studies, the binding data on the left generates more accurate and reproducible results.

FIG. 1 & 2